Table of Contents

From predictive maintenance and quality control to supply chain management and workflow optimization, use of AI in manufacturing and other technologies like machine learning and robotics are streamlining processes and minimizing downtime. This blog explores how AI-driven solutions are empowering manufacturers to make data-driven decisions, improve productivity, reduce costs, and deliver higher-quality products.

The future seems intriguing for businesses, organizations and the rest of the world with artificial intelligence playing a crucial role in digital transformation. Even for the manufacturing industry as there will be machines capable enough to predict their maintenance timeline and requirements. You’ll see robots working alongside humans to improve productivity and optimize processes.

All the credit for this transformation goes to AI in manufacturing. Its advanced technologies are transforming traditional manufacturing into a smart, efficient, and highly innovative industry.

But how does AI work for manufacturing?

What changes is it bringing in the industry?

How does it enhance efficiency and encourage innovation?

In this blog, we’ll explore real-world examples of how AI is used to predict equipment failures before they happen, ensure the highest quality of products, optimize supply chains, and even create entirely new manufacturing processes.

How is AI Used in Manufacturing?

Artificial Intelligence (AI) in manufacturing refers to the use of advanced algorithms and machine learning techniques to enhance and optimize production processes, improve efficiency, and foster innovation. It includes the integration of AI technologies, like computer vision, predictive analytics, robotics, and machine learning into various stages of manufacturing.

By leveraging AI, manufacturers can automate complex tasks, make data-driven decisions, and predict and mitigate issues before they become significant problems. For instance, if a machine starts vibrating more than usual, the AI system alerts maintenance teams before a breakdown occurs.

Take another example, if a particular step in the production process is taking longer than usual, AI can suggest adjustments to speed up the workflow, reduce cycle times, and increase overall productivity. Along with these, there are many ways to implement AI in the manufacturing industry and reap the benefits of the emerging technology.

Market Overview of AI Adoption in Manufacturing Industry

According to Precedence Research, the global AI in the manufacturing market was valued at USD 3.8 billion in 2022. It is forecasted to reach around USD 68.36 billion by 2032, exhibiting an impressive compound annual growth rate (CAGR) of 33.5% from 2023 to 2032.

Capgemini Research Institute surveyed 300 major manufacturers and revealed that Europe is at the forefront of integrating AI into manufacturing operations. The report says that over half of the European manufacturers surveyed are adopting AI solutions, with Japan and the US trailing behind in second and third positions, respectively.

In Europe, Germany has 69% of its manufacturers implementing at least one AI use case in their operations. France follows with 47%, and the UK with 33%. The increasing recognition of AI’s potential, along with robust government support across various countries, is likely aiding manufacturing companies in embracing AI in their operations.

| The PwC survey says that 54% of firms in India are increasingly adopting artificial intelligence and analytics. Deloitte’s survey on AI adoption in manufacturing revealed that 93% of companies view artificial intelligence as a crucial technology for innovation. The IBM 2022 Global AI Adoption Index report indicated that 1 in 4 companies are adopting AI solutions due to labor and skill shortages. McKinsey predicts that by 2030, the penetration of AI in the manufacturing industry will contribute nearly 19% to China’s economic growth. |

AI statistics prove that AI in the manufacturing industry is poised for significant growth, driven by the need for increased efficiency, improved quality, and cost reduction. As AI technologies evolve, their adoption in manufacturing will accelerate, leading to smarter, more agile, and streamlined manufacturing operations worldwide.

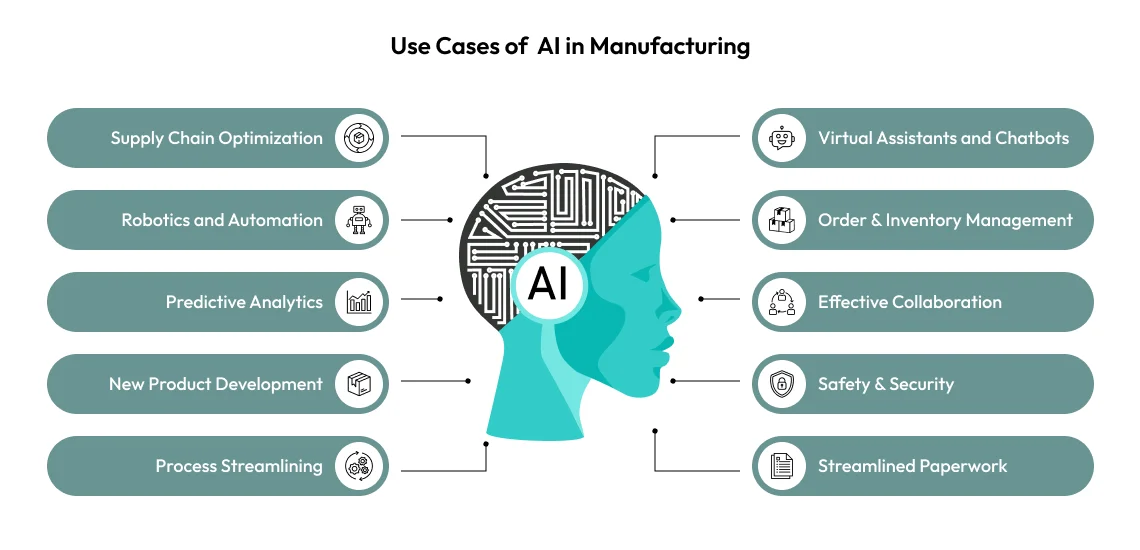

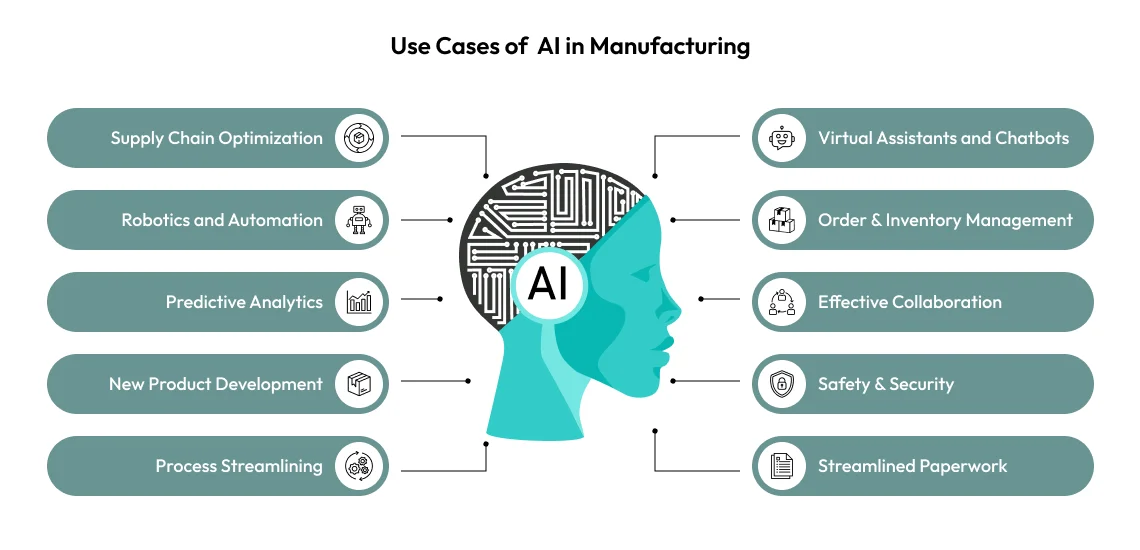

Top Use Cases of AI in Manufacturing with Examples

The latest statistics on AI have proven the worth of this technology by highlighting its growth opportunities and capabilities. To get a broader perspective, now is the time to understand AI use cases in manufacturing. So, let’s start with that!

Supply Chain Optimization

Artificial Intelligence (AI) significantly enhances supply chain optimization in manufacturing by providing real-time data analysis, predictive insights, and automation capabilities. AI algorithms analyze vast amounts of data from various sources, such as production lines, inventory levels, and market demand, to identify patterns and predict future trends.

This predictive capability allows manufacturers to anticipate demand fluctuations and adjust their production schedules and inventory levels accordingly, reducing waste and minimizing costs. Additionally, AI-powered automation streamlines operations by managing routine tasks, such as inventory management and order processing, freeing up human resources for more complex decision-making tasks.

For example, a consumer electronics manufacturing company leverages generative AI, ML algorithms and other AI types to improve supply chain efficiency. By utilizing AI to analyze sales data and global market trends, the company can predict which products, such as smartphones and laptops, will see increased demand.

AI systems then optimize the procurement of necessary components, ensuring a just-in-time inventory approach that minimizes excess stock while preventing shortages. In the production process, AI monitors machine performance and detects maintenance needs before failures occur, reducing downtime and ensuring a steady workflow.

Additionally, AI-driven logistics systems analyze shipping routes and delivery schedules, optimizing transportation to reduce costs and delivery times. Consequently, the company achieves greater efficiency, lowers operational costs, and improves its ability to meet customer demands swiftly and accurately.

Robotics and Automation

By integrating AI with robotic systems, manufacturers can achieve advanced automation capabilities, where machines can learn and adapt to various tasks without human intervention. AI algorithms enable robots to perform complex operations, including quality control inspections, assembly tasks, and predictive maintenance, with high accuracy and consistency.

Moreover, AI-powered robots can analyze data from sensors and cameras in real time, making intelligent decisions on the fly, thus improving overall productivity and reducing downtime.

For example, in an automotive manufacturing plant, AI is integrated with robotic aims to streamline the assembly line. These AI-powered robots are equipped with machine-learning algorithms that allow them to adapt to different car models being produced on the same line.

If a new car model enters the production line, the robots automatically adjust their operations. It takes care of welding, painting, and assembling components, without demanding reprogramming.

Predictive Analytics

AI can analyze historical data, identify patterns, and predict future outcomes with high accuracy. This capability enables manufacturers to foresee potential issues, optimize maintenance schedules, manage inventory levels effectively, and improve overall decision-making processes.

Predictive analytics powered by AI helps in anticipating equipment failures, demand fluctuations, and supply chain disruptions. It minimizes downtime, reduces costs, and enhances efficiency. In other words, AI algorithms will analyze the data in real time, identifying patterns that indicate normal and abnormal operating conditions.

When the AI system detects deviations from these patterns, it predicts potential equipment failures and recommends maintenance actions before a breakdown occurs. This proactive approach allows the company to perform maintenance during scheduled downtimes, avoiding unexpected interruptions in production.

New Product Development

Companies can use generative AI, machine learning algorithms and data analytics to analyze large amounts of market data, emerging trends, and customer feedback to identify new opportunities and consumer needs. It helps manufacturers to make informed decisions about product features, design modifications, and market positioning.

Moreover, AI-driven simulation tools help manufacturers make informed decisions about product features, design modifications, and market positioning. Additionally. AI-driven simulation tools and generative design software allow for rapid prototyping and testing of various design iterations, significantly reducing the time and cost associated with traditional product development or full-cycle product development.

Process Streamlining

Integration of AI and ML in business processes of the manufacturing industry help identify inefficiencies, predict maintenance needs, and suggest improvements in various stages. AI systems can monitor production lines, analyze performance data, and make real-time adjustments to enhance productivity and reduce waste. By using AI into manufacturing operations, companies can achieve greater consistency, lower costs, and faster turnaround times, ultimately boosting overall efficiency.

For instance, a pharmaceutical manufacturing company integrates AI into the drug production process. The AI system will monitor the entire production line, collecting data on variables such as temperature, pressure, and mixing times.

By analyzing this data, AI identifies optimal conditions for each stage, ensuring that every batch of medication meets stringent quality standards. Additionally, AI detects deviations from these optimal conditions and automatically makes adjustments to maintain consistency.

Demand Forecasting

Artificial intelligence algorithms provide precise, data-driven insights that enable companies to anticipate customer needs and adjust their production schedules accordingly. Utilizing machine learning algorithms and synthetic data, AI analyzes historical sales, market trends, seasonal patterns, and external factors such as economic indicators or social media sentiment to predict future demand with high accuracy.

It allows manufacturers to optimize inventory levels, reduce the risk of overproduction or stockouts, and improve overall operational efficiency. Hence, companies can make more informed decisions regarding resource allocation, supply chain management, and marketing strategies.

For example, a fashion apparel manufacturer employs AI to improve its demand forecasting. The AI system gathers and analyzes data from various sources, including past sales records, fashion trends on social media, weather forecasts, and promotional calendars. It processes diverse data sets to predict styles, colors, and sizes in high demand for the upcoming season.

The company can also know popular items and upcoming AI technology trends of the industry or business and produce items in sufficient quantities while avoiding excess inventory of less popular items.

Virtual Assistants and Chatbots

AI chatbots and virtual assistants can handle various tasks, from answering common customer inquiries to assisting with inventory management and order tracking. They can automate routine interactions. Virtual assistants and chatbots free up human resources for more complex and value-added activities. They provide instant, accurate responses around the clock, ensuring efficient communication and quick resolution of issues.

They can answer questions about product specifications, pricing, and availability and guide customers through the process of placing orders, troubleshooting common issues, and scheduling maintenance services.

Order & Inventory Management

AI automates processes, optimizing stock levels, and improving demand forecasting. It can predict demand trends, adjust inventory levels dynamically, and streamline the ordering process. It ensures that manufacturers maintain optimal inventory levels, reducing overstock and stockouts, and improving overall operational efficiency.

Additionally, AI systems can automate routine tasks such as order processing and reordering of supplies, freeing up human resources for more strategic activities.

Moreover, when inventory levels reach a predefined threshold, the AI system can place orders with suppliers, ensuring timely replenishment. The AI system also monitors supplier performance and lead times, adjusting order quantities and timings to account for any potential delays.

Effective Collaboration

AI-powered tools and platforms enable real-time collaboration by integrating data from various sources, providing a unified view of operations, and offering actionable insights. These tools can automate routine tasks, manage project workflows, and ensure that all team members have access to the latest information.

The collaboration will reduce misunderstandings and improve coordination. AI also supports remote collaboration by providing virtual workspaces and communication tools that keep teams connected regardless of their physical location.

Safety & Security

Through advanced data analysis, machine learning algorithms, and real-time monitoring, AI can detect patterns that indicate potential safety risks or security threats. AI systems can analyze data from various sensors and cameras to monitor equipment performance, worker behavior, and environmental conditions, allowing for immediate corrective actions when anomalies are detected.

Additionally, AI enhances cybersecurity by identifying and responding to potential threats, ensuring that manufacturing systems and sensitive data are protected from cyberattacks. If a potential hazard is identified, the AI system immediately alerts the relevant personnel and can initiate automated safety protocols, like shutting down equipment or activating security systems.

Streamlined Paperwork

Through the use of natural language processing (NLP) and machine learning algorithms, AI can efficiently handle large volumes of paperwork, reducing the time and effort required for manual processing.

AI systems can extract relevant information from various documents, categorize and store them appropriately, and even analyze the data to generate reports. This automation not only minimizes human error but also ensures that documents are easily accessible and up-to-date, improving overall operational efficiency.

What’s the Future of AI in Manufacturing?

AI in manufacturing has a lot to offer to the industry. These future technologies represent the next frontier in AI for manufacturing, promising to redefine how factories operate, innovate, and adapt to evolving market demands in the coming years. Here are some of the key advancements on the horizon:

Wearable Technologies

These devices will support real-time health monitoring, hazard detection, and ergonomic feedback. They can continuously monitor vital signs like heart rate and body temperature, alerting workers and supervisors to potential health risks or fatigue-related issues.

AI algorithms enable wearables to detect environmental hazards such as toxic gases or unsafe temperatures, providing immediate alerts for prompt action. Additionally, wearables provide feedback on ergonomic practices, promoting safer work behaviors and reducing the risk of musculoskeletal injuries.

Autonomous Vehicles

Autonomous vehicles use sensors and AI to move materials and products around factories without requiring human attention. They reduce the chance of accidents, run all the time, and take the best routes, making work faster and more efficient. They can also quickly react to changes in production needs or problems.

Digital Twins Simulations

These digital twins use real-time data and analytics to simulate and predict behavior, performance, and outcomes in a controlled environment. By creating a digital counterpart of a manufacturing plant, equipment, or product, manufacturers can test different scenarios, optimize processes, and identify potential issues before they occur in the real world.

3D Printing

This technology will allow manufacturers to create complex geometries and intricate designs directly from digital models, reducing the need for traditional tooling and assembly processes.

3D printing will enhance flexibility in production, facilitate rapid iterations of product designs, and lower production costs for small-batch or customized products. It also enables on-demand manufacturing and localized production, reducing lead times and transportation costs.

In conclusion, AI’s future in manufacturing looks promising for transforming how things are done and driving steady growth. Looking ahead, investing in AI will be crucial for shaping the next phase of manufacturing, where smart systems and human creativity work together to set new industry standards and bring more value to businesses and customers. To capture this growth, you must hire AI developers to integrate AI solutions in your manufacturing company or plant.

Achieve Manufacturing Innovation with MindInventory’s AI Expertise

MindInventory is a leader in providing technologically advanced AI development services. Whether it is automating routine tasks, optimizing supply chain operations, or enhancing product quality, our team designs AI systems that integrate seamlessly with existing operations and address specific challenges, simplifying the overall manufacturing process.

With a proven track record in AI implementation across diverse industries, MindInventory offers reliability and innovation, leveraging cutting-edge technologies to deliver tangible business outcomes. Our approach to AI implementation in manufacturing is rooted in a thorough understanding of industry-specific requirements and compliance standards. They collaborate closely with manufacturers to assess needs, define objectives, and develop tailored strategies that align with business goals.

FAQ About AI in Manufacturing

The four types of AI technologies are Reactive Machines, Limited Memory AI, Theory of Mind AI, Self-aware AI, etc. Each type represents a progressive evolution in AI’s ability to interact with and adapt to its environment, ranging from rule-based reactive responses to potential future states of consciousness and self-understanding within machines.

AI is increasingly utilized in production settings across industries worldwide. AI technologies like machine learning and robotics are transforming manufacturing processes by automating tasks, optimizing resource allocation, and improving decision-making through data analysis.

Mainly, there are 5 use cases of Generative AI in the manufacturing industry for monitoring machine-generated events, automating customer service, searching and synthesizing documents, discovering product/content catalogs, advising on supply chain management, etc.

AI is used in product development, predictive maintenance, real-time process monitoring, supply chain optimization, order management, assembly line optimization, automated defect detection, cobots (collaborative robots), and other aspects of the manufacturing industry.