Table of Contents

AI inventory management is outperforming the traditional way of inventory management. From predictive analytics to demand forecasting, automated replenishment, and many more, AI is transforming the entire inventory management with greater efficiency. This blog discusses everything about AI inventory management and how it’s revolutionizing supply chain management.

Inventory management has grown into a complex task in today’s fast-paced world. As businesses are expanding, catering to a wider pool of customers globally, efficient inventory management is the need of the hour to stay competitive. Thanks to AI inventory management, it makes end-to-end inventory management a breeze.

Businesses today tend to prioritize seamless inventory management, especially with the proliferating significance of omnichannel fulfillment. Be it Amazon’s “Kiva Robots”, Walmart’s “Eden” or Zara’s “POS (Point of Sale)” system, they all pave the way to highly-tailored and flawless inventory management.

Besides, big brands like Coca-Cola, Sephora, and L’Oreal also make use of AI-enabled systems for inventory management, ensuring their inventory is aligned with the customer’s needs and preferences.

By harnessing the power of artificial intelligence inventory management, businesses can unlock the next level of efficiency, accuracy, and agility throughout the supply chain. This blog navigates you through a detailed exploration of the role of AI in inventory management. It’ll help you to know and implement it in your business for better profitability.

What Is AI Inventory Management?

AI inventory management involves utilizing AI technologies to automate and optimize inventory management procedures. With data analysis, machine learning (ML), and predictive analytics, AI enhances inventory management, transforming the traditional way of doing the same. From demand forecasting to supplier management and replenishment, AI tends to revolutionize the conventional way of inventory management.

AI in inventory management helps businesses maintain the appropriate quantity of goods to meet real-time customer requirements. It keeps demand and supply aligned by reducing the chances for overstocking and stockouts, minimizing holding costs, and maximizing business profitability.

How Is AI Used In Inventory Management?

AI makes use of advanced algorithms and machine learning techniques and analyzes a wider dataset for demand forecasting. Unlike traditional methods that depend on manual input and analysis, AI-powered systems are able to process data at a streamlined speed and scale. They are competent in detecting patterns and trends using data.

AI-enabled inventory management solutions scrutinize historical sales data, customer behavior, market trends, and additional relevant factors to gauge and reveal insights for future predictions.

With predictive analytics, AI-enabled inventory management allows businesses to have a better understanding of real-time requirements, optimize stocks, and anticipate the changes in demand for the future.

What’s more, AI-powered inventory management systems learn continuously and adapt over time. Through feedback loops and ongoing data analysis, AI systems refine algorithms and models to reflect evolving marketing dynamics and business scenarios. This adaptive capability allows businesses to stay agile and responsive and efficiently deal with this competitive marketplace.

Use Cases Of AI In Inventory Management

AI has a wide range of use cases for inventory management, including real-time visibility, anomaly detection, demand forecasting, supplier management, warehouse operations, automated replenishment, and many more. It equips businesses with robust tools, assisting them to optimize inventory levels, minimize stockouts and overstocks, and promote productivity and profitability.

Demand Forecasting

AI enables businesses to dynamically respond to market fluctuations. Employing sophisticated machine learning algorithms, AI meticulously assesses various data points such as historical data, market trends, and external influences to help businesses gain deeper insights into customer behavior and demand patterns for the future, known as demand forecasting.

Using AI for demand forecasting and predictive analysis of the market’s future is critical to effective and efficient inventory management. Accurate demand forecasting limits the risk of stockouts and overstocks, ensuring an excellent equilibrium of the inventory level, reducing costs, and promoting profitability.

Real-Time Visibility

Leveraging the power of RFID & IoT sensors, real-time stock visibility, AI-powered stock alerts, automated storage & retrieval systems (ASRS), and many more, AI provides real-time visibility into inventory locations.

IoT networks made up of physical objects such as inventory items embedded with sensors, software, and network connectivity allow a larger pool of data collection and sharing. AI assists businesses in analyzing a wide range of data and extracting intensive insights to ensure real-time monitoring and maintenance of inventory levels.

Anomaly Detection

AI in inventory management makes use of machines to spot anomalies like stock discrepancies, unexpected demand fluctuation, or supply chain disruptions. Machine learning algorithms process a large amount of real-time data sets from IOT sensors and historical trends and detect unusual patterns, triggering alters and preventing error in inventory.

That level of anomaly detection competency allows businesses to react quickly to potential issues, maintaining integrity and operational efficiency throughout the inventory levels.

Inventory Classification

Leveraging sensors, AI-enabled inventory management can classify products based on their weight, temperature, location, motions, and many others, ensuring an efficient arrangement of the products throughout the inventory. That level of detailed automation streamlines the organization and management of diverse inventory.

When items throughout the inventory are categorized and organized well, businesses can optimize storage, streamline retrieval procedures, and ensure informed decision-making for inventory replenishment and allocations.

Scenario Simulation

AI-powered scenario simulation allows businesses to model a variety of market scenarios and scrutinize their impacts on various inventory levels. This very ability allows organizations to prepare for fluctuations in market demand and develop agile strategies for inventory that can quickly adapt to the ever-evolving market demands and conditions.

Returns Management

By analyzing returned products, identifying patterns, and anticipating return rates, AI in inventory management speeds up the processes of returns management. It automates the processes by categorizing returns, optimizing restocking, and identifying issues relating to quality.

The very procedure allows for improved decision-making, minimizes return-related expenses, and elevates customer satisfaction by efficiently and effectively handling reverse logistics.

Supplier Management

AI data analytics tools allow an intensive analysis of supplier performance metrics. These tools are efficient in assessing factors like delivery times, quality pricing, and many more. Leveraging AI-driven insights, businesses leverage strategic coordination with suppliers to make sure they have the right amount of inventory at the right time. Effective supplier management helps streamline the procurement process, lessen lead times, and circumvent overstocks and stockouts for business profitability.

Automated Replenishment

With continuous monitoring and real-time data collection in terms of stock levels, AI inventory management ensures automated replenishment. It performs real-time monitoring of stock levels and automatically triggers orders when inventory falls below ascertained thresholds.

It optimizes the replenishment processes, mitigating the risks of both overstock and overstock. Besides, it helps organizations to ensure efficient product availability without excessive inventory expenses for optimized profitability and business growth.

Warehouse Operation

Leveraging competencies of AI-powered sensors, for example, RFID and IoT devices, AI-enabled inventory management gathers real-time data and optimizes warehouse operations such as layout design, fulfillment process, and the like. AI algorithms tend to analyze the data on demand trends, product sizes, and turnover rates to recommend the most efficient storage feasibility.

An efficient warehouse operation helps accelerate workflows and minimize lead times and operational expenses, ensuring overall functionality, operation, and a boost in profitability.

Real-Life Use Cases of AI In Inventory Management

From predictive analytics to smooth operations across inventory levels, AI in inventory has a larger role to play for businesses. Many renowned brands like Amazon, Walmart, Coca-Cola, L’Oreal, and Zara are leveraging AI’s competencies for efficient inventory management. Following are a few of the best AI inventory management software you should know!

Amazon’s “Kiva Robots”

- Use Cases: Amazon uses AI-enabled robots to automate multiple tasks in fulfillment centers like sorting, picking, and transporting products. Empowered by machine learning, these robots enable Amazon to calculate the fastest route for picking and shipping products and accelerate workflow with minimized human errors.

- Benefit: These robots tend to work in coordination with AI algorithms, speeding up order fulfillment, minimizing human errors, and optimizing space in the warehouse.

- Result: AI-powered robots enable Amazon to handle gazillions of products at any given time, with highly efficient inventory control and streamlined delivery time.

Walmart’s “Eden”

- Use Case: One of the largest global retailers, Walmart, employs AI to optimize inventory management through efficient demand forecasting. It uses machine learning algorithms to analyze historical data, seasonal trends, and external factors like weather and promotions to anticipate product demand in specific stores.

- Benefit: It enables Walmart to effectively manage stock levels and mitigate waste caused by overstocking while also circumventing stockouts. These systems dynamically make adjustments to replenishment rates based on real-time data.

- Result: The AI-driven inventory management helps Walmart to ensure the appropriate availability of products in real time, reducing cost, improving customer satisfaction, and thereby, overall business profitability.

Coca-Cola’s Freestyle System (Formerly Known as Freestyle Vending Machine)

- Use Case: Coca-Cola implements AI-powered demand forecasting models, allowing it to predict regional demands for products. It uses AI to optimize warehouse management by pinpointing patterns in product movement and ascertaining the best strategies for storage.

- Benefit: With the very system, Coca-Cola adjusts inventory levels at multiple levels at various distribution centers while circumventing the scenarios of running out of stocks and overstocking.

- Result: Coca-Cola ensures efficient warehouse operations and better alignment in inventory with accrual customer demand. This way, it can reduce waste and improve overall efficiency in the supply chain.

Sephora’s Intelligent Replenishment System

- Use Case: A global beauty retailer, Sephora, leverages an AI-powered inventory system to analyze sales data and anticipate product demands across its stores and online platforms. AI tools help it adjust stock levels aligned with factors like customer behaviors, trends, and seasonal shifts, optimizing inventory levels.

- Benefit: The system benefits Sephora by tailoring the replenishment strategies and ensuring certain products are stocked in specific locations based on demand.

- Result: Using AI-enabled inventory management software, Sephora is capable of reducing waste and elevating customer experience by keeping the right products available when customers require them.

Zara’s “POS (Point of Sale)” System

- Use Case: A global fashion retailer, Zara leverages AI to keep track of real-time inventory levels across its wider store networks. Embracing RFID (Radio Frequency Identification) tags and AI-driven systems, it tracks demand trends and product movement in stores, warehouses, and distribution centers.

- Benefit: Integrating AI in inventory management allows Zara to timelessly replenish stocks and transfer inventory among stores as per demand. Besides, it helps in accurate inventory forecasts, minimizing outstocks and overstocks for better profitability.

- Result: Zara, leveraging AI-powered systems, is capable of ensuring that the items more in demand are available in the store, circumventing lost sales and boosting customer satisfaction.

L’Oréal’s “Supply Chain 4.0”

- Use Case: L’Oréal leverages AI and machine learning models for inventory management. AI algorithms analyze global demand patterns, production cycles, and logistical factors to anticipate inventory across multiple locations.

- Benefit: The system automates stock replenishment and production schedules and lets L’Oreal reduce excessive inventory stocks, stockouts, as well as transportation expenses.

- Result: L’Oreal, by adopting an AI-powered inventory management system, can significantly lower costs and meet customer demands with optimized accuracy.

Industries Leveraging AI for Efficient Inventory Management

Businesses from multiple industries like food and beverage, healthcare, manufacturing, retail and many more are leveraging the power of AI inventory management. Here are a few examples of the industries using AI to manage their inventory:

Food & Beverage

Businesses dealing in the food and beverage industry use AI to keep track of perishable goods, minimize waste, and ensure an appropriate availability of fresh stock. Restaurants can leverage AI to analyze historical sales data and make adjustments to the menus based on popular products and market trends.

Health And Pharmaceuticals

Businesses in the health and pharmaceutical industry use AI for inventory management, allowing them to manage medical supplies and equipment efficiently. It helps them reduce shortages and improve patient care. Drug manufacturers and pharmacies leverage AI to manage complex inventories and maintain compliance with regulations while managing the expiration dates of medicines.

Manufacturing

Manufacturers leverage AI’s potential to plan for production based on demand forecasts and required inventory levels. They can use AI in manufacturing for just-in-time inventory. AI helps manufacturers maintain a lean inventory level, minimizing carrying costs and waste for better profitability.

Wholesale & Distribution

Wholesalers use AI for inventory management, which helps them optimize inventory across locations. They utilize AI in a variety of ways, like demand forecasting, real-time inventory tracking, and many more, to enhance efficiency, minimize cost, and optimize stock levels.

Retail

Retailers utilize AI technologies like computer vision to manage seasonal demand, optimize stock levels, and elevate overall customer experiences through efficient inventory tracking and warehouse management.

Construction

Construction companies make use of AI inventory management software intending to anticipate demand for required construction materials based on historical data, external factors, and project timelines to optimize procurement with no delay.

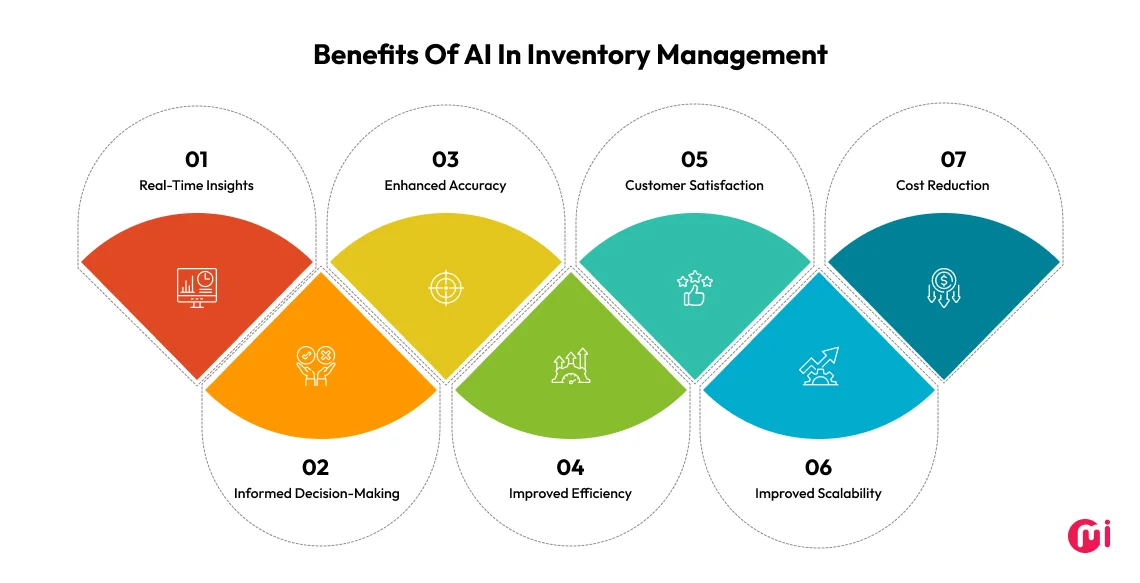

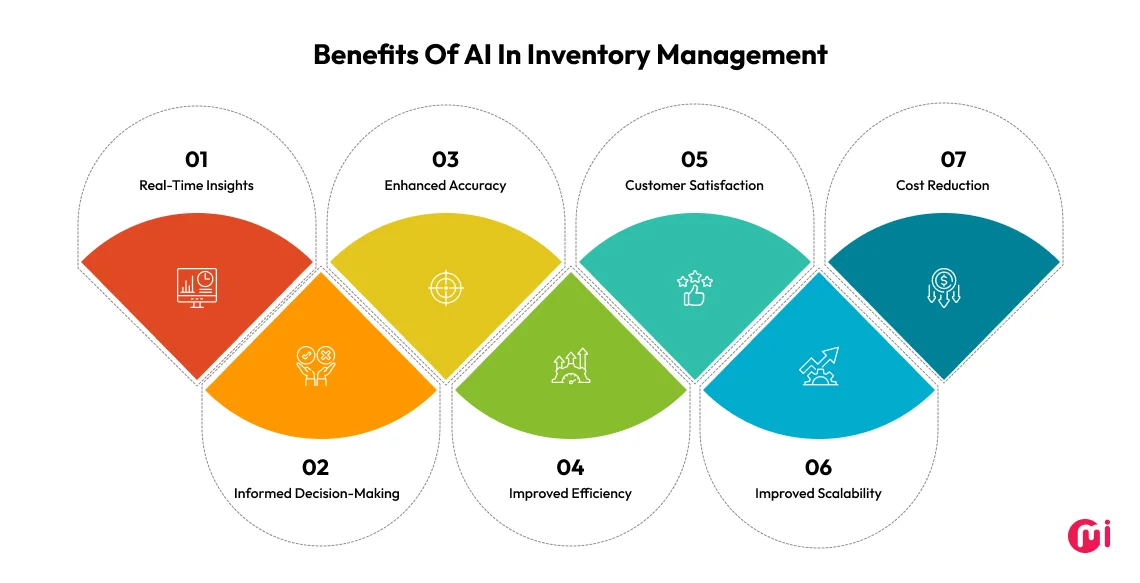

What Are The Benefits Of AI In Inventory Management?

Right from real-time insights to efficient decision-making, enhanced accuracy and efficiency, cost reduction, and better profitability, AI has a wide range of benefits for businesses of multiple types. Although they are numerous, here are the top-notch benefits of AI in inventory

1. Real-Time Insights

The advanced algorithms of AI excel at analyzing large data sets for demand forecasting, providing businesses with real-time visibility into inventory levels, movement, and the latest trends across locations. It allows businesses to make informed decisions for replenishment, allocation, and pricing, reducing the likelihood of overstocks and outstocks to ensure enriched profitability.

2. Informed Decision-Making

AI-powered systems are most likely to adapt to the ever-evolving changes in the business and inventory systems. It assists businesses to scale their operations with agility without losing efficiency and the quality of services.

3. Enhanced Accuracy

AI-powered algorithms perform sophisticated data analytics and machine learning techniques to process large amounts of inventory data timelessly and accurately. It mitigates the risk caused by human errors when making entries and analyses manually. It leads to precise inventory forecasts, order recommendations, and inventory tracking.

4. Improved Efficiency

By automating repetitive tasks such as data entry, analysis, and decision-making, AI streamlines the overall inventory management processes. It helps businesses eliminate manual errors, allowing them for efficient resource allocation. It helps employees save their precious time and focus on high-priority tasks such as strategic planning and customer services.

5. Customer Satisfaction

As it helps businesses predict customer demand and respond to it accordingly, AI inventory management ensures enriched customer satisfaction. With accurate inventory forecasts and tailored product recommendations, AI helps you ensure the appropriate product availability of customized products, which leads to higher customer satisfaction and loyalty.

6. Improved Scalability

AI-driven inventory management solutions scale with constantly evolving needs and adapt to the complexities and challenges with no need for manual intervention. It helps companies to expand their operations, enter new markets, or even introduce new products with ease.

7. Cost Reduction

AI inventory management helps organizations optimize inventory levels at a minimized operational cost. The AI-powered demand forecasting and inventory optimization algorithms enable organizations to maintain optimal stocks and reduce excessive inventory stocks, resulting in lower costs and better profitability.

What Are The Challenges Associated With AI Inventory Management?

Although AI inventory management has a plethora of benefits, it might have some drawbacks like initial investment, data issues, resistance to change, and security concerns that you should be aware of beforehand.

- Initial Investment: AI for inventory management comes with some initial expenses. These involve software acquisition and integration, along with the expenses for training employees.

- Data Issues: AI-based inventory management relies on high-quality data to produce accurate results. In case the data isn’t accurate or incomplete, it can generate flawed, incomplete, or outdated predictions.

- Integration with Existing System: Integrating AI-powered systems with legacy systems such as ERP, supply chain management, or legacy point-of-sale systems tends to be increasingly complex and expensive. When there are mismatched data formats and incompatible software systems, they can cause disruptions.

- Resistance to Change: Employees may be resistant to change when their organization adopts new technologies. To efficiently tackle this challenge, businesses need change management, communication, and an ample amount of training for employees.

- Over Reliance on Automation: Although, automation is one of the key benefits of AI in inventory management, overly relying on the same can lead to minimized human oversight. In this case, mistakes committed by AI systems are more likely to go unnoticed when there’s no sufficient manual intervention or timely check conducted.

- Security & Compliance Concerns: AI-powered systems need access to sensitive business data, including sales transactions, inventory levels, and crucial customer information. Lack of security can lead to vulnerability against cyberattacks, resulting in data breaches and huge financial losses.

Choose MindInventory to Future-Proof Your Inventory System with AI

Mindinventory is a client-centric AI development company, providing businesses with a wide range of AI-enabled software solutions. Bipedai, Novatech, and many others are among the high-end software solutions we have built for businesses.

Bipedai is a mobile app designed to complement the AI-enabled smart navigation harness. When implemented, the client experienced an exceptional outcome, which is a 75% increase in Obstacle Avoidance Efficiency, a 60% decrease in navigation-related stress, and a 50% boost in user satisfaction when it comes to GPS instructions.

Novatech is an AI chatbot for construction, providing optimal help to workers on construction sites. When implementing our solution, Novatech experienced a 71% improvement in site safety awareness, a 59% cut-down in hazardous events, and a 56% betterment in work collaboration.

The above-mentioned are just a glance; however, we have worked on various AI-powered projects for businesses of all sizes and domains. Our AI developers own expertise in Gen AI, computer vision, deep learning, robotic process automation and many more.

If you, too, need to future-proof your inventory system with AI, we can be the right destination for the same. Yes, we help you with complete AI development services, meeting your comprehensive business needs with ease.

FAQs On AI In Inventory Management

AI-powered inventory management systems play a crucial role in smooth supply chain management. These solutions conduct inventory tracking, demand forecasting, automated replenishment, quality control, predictive maintenance, and many more, ensuring a seamless and flawless business operation.

Right from analyzing a wide array of historical data to conducting predictive analytics and demand forecasting, AI inventory management has completely transformed the traditional way of inventory management. It eliminates overstock and stockouts and fosters inventory management that meets the real-time needs of customers while limiting expenses and promoting profitability.

AI in inventory management processes a wide range of historical data and external patterns like seasonality, promotions, and even weather patterns for predictive analysis and demand forecasting. By forecasting demands, it automates replenishment processes and maintains appropriate inventory, circumventing overstocks and stockouts for better profitability.